ASTM A240 304L stainless steel plate phase diagram Manufacturer

Content

ASTM A240 304L stainless steel plate 1.4307 Manufacturer

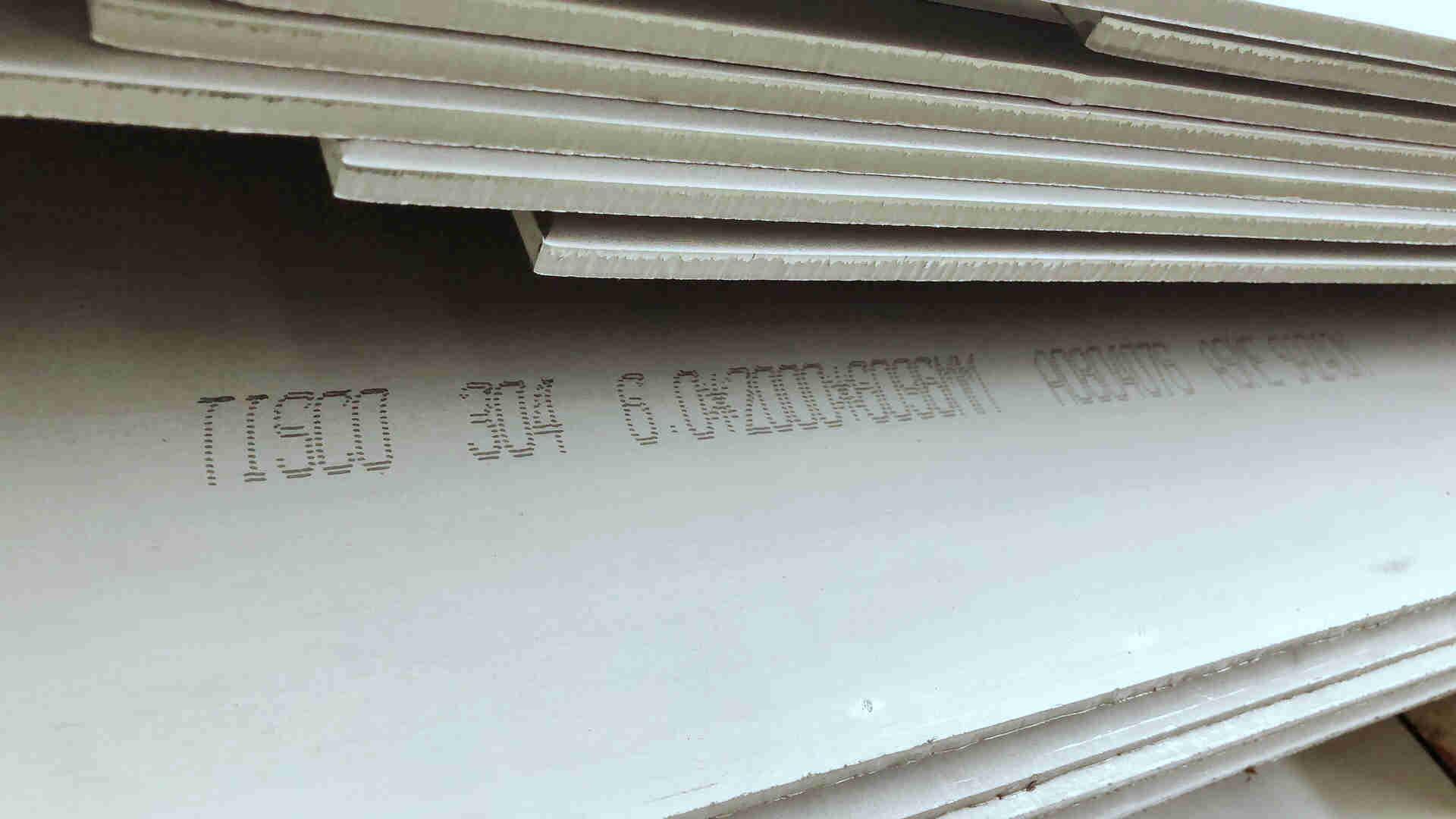

gangsteel supply astm a240 304l Stainless steel plate thickness 1mm to 300mm. the max width 2800mm. We also provide laserjet and water jet cutting for stainless grade astm a240 304l,astm a240 type 304l.a240 304l material cutting parts,a240-304 machine parts,a240 304 flat bar ,sa240 304l welded pipe.

a240 grade 304 seamless pipe,a240-304l waterjet cutting disc,a240-304 material,a240 tp304l laser cutting parts,astm a240 304l mechanical properties,astm a240 304l chemical composition,astm a240 304l properties,a240,gr 304l Origin China,sa240 tp 304l angle bar,a240 type 304l square pipe,sa240 type 304l angle steel mill,astm a240 304l stainless steel,astm a240 304l density,astm a240 304l specification.

Below 1700°F there could be speedy formation of intermetallic phases because of the combination of temperature and deformation. Whenever scorching forming is completed, it must be followed by a full solution anneal at 1900°F minimal and rapid quench to revive part stability, toughness, and corrosion resistance. Stress relieving is not required or really helpful; nonetheless, if it should be carried out, the material ought to receive a full resolution anneal at 1900°F minimum, adopted by speedy cooling or water quenching. Alloy 2205 duplex stainless steel plate combines excessive power and excessive corrosion resistance to provide excessive corrosion fatigue strength.

People also ask:cres 304l|a240 304l|304l yield strength|tensile strength of ss 304|ss 304l price|sa240 tp304l|1.4306 steel|ss 304 material specification|1.4307 stainless|sa213 tp304l|304l stainless steel chemical composition|aisi 304l mechanical properties|304l mechanical properties|ss 304 round bar price|304 and 304l|din 1.4307|aisi 304l chemical composition|sa 240 gr 304 material|304 round bar|ss 304l material properties|304l properties|a312 304l|304l stainless steel yield strength|aisi 304l 2b|ss304l material|304l sst|ss 1.4307|304l 2b|sa 240 gr 304l|astm s30400|304l carbon content|din 1.4306|aisi 304l properties|1.4307 aisi 304l|304l material properties|astm a312 304l|ss 304 round bar suppliers|aisi 304l composition|uns s30400 mechanical properties|sae 304l|type 304l|1.4307 stainless steel properties|sa 240 gr 304l mechanical properties|sst 304l|aisi 304l specification|1.4306 specification|astm a240 type 304l|304l austenitic stainless steel|1.4307 material properties|

This permits a designer to save lots of weight and makes the alloy extra cost competitive when compared to 316L or 317L. Alloy 304H is a modification of Alloy 304 in which the carbon content material is managed to a variety of 0.04-0.10 to supply improved excessive temperature strength to elements uncovered to temperatures above 800°F. 316/316L metal has excellent corrosion resistant properties, whether or not it is atmospheric or oxidizing setting, even for marine environment, it reveals excellent corrosion resistance in welded state. Normally 316/316l metal shows no magnetic in annealed situation, cold drawn or chilly rolling process may make it with little magnetic, and it can be fastened with further processing. Possible Alternative GradesPossible different grades to grade 304 stainless steels are given in table 5.

What is the best grade of stainless steel?

Type 304: The best-known grade is Type 304, also known as 18/8 and 18/10 for its composition of 18% chromium and 8%/10% nickel, respectively. Type 316: The second most common austenitic stainless steel is Type 316.

In common, all three grades are being elongated via the maximum restrict of 40%. Also, they’ve the highest melting level at 1400 levels Celsius apart from the 304H. Our Stainless Steel 317 Sheets is commonly used for Oil & petroleum refining gear,Pulp and paper processing gear, Food processing tools, Soap and photographic handling gear, and so forth. Stainless metal plate is sometimes called “corrosion-resistant steel” – it does not stain, corrode or rust as easily as regular carbon steel. It differs significantly from standard carbon steel as a result of quantity of chromium present, which limits surface corrosion in contrast to carbon metal which is able to rust when uncovered to air and any moisture within the ambiance. Due to its anti-oxidation qualities, stainless-steel is often a popular solution.

- What is ASTM A240 304L Stainless steel grade?

304L stainless steel is a universal stainless-steel material.

Grade of 304L stainless steel:

The old standard JB / T 4237-1992 corresponds to 00Cr19Ni10

New standard GB / T 20878-2007 grade and chemical composition of stainless steel and heat resistant steel

And GB 24511 2009 stainless steel plate and strip for pressure equipment

Corresponding to 022cr19ni10, its carbon content is about 0.03%

The unified digital code s30403 is different from s30408 of 304

- What is Stainless steel ASTM a240 304l chemical composition and astm a240 304l mechanical properties?

Analysis of chemical composition% of 304L stainless steel

Carbon C: ≤ 0.03,

Silicon Si: ≤ 1.0,

Mn: ≤ 2.0,

Cr: 18.0-20.0,

Ni: 9.0-12.0,

Sulfur s: ≤ 0.03,

Phosphorus P: ≤ 0.045;

mechanical property

The mechanical properties of 304L stainless steel are as follows

Yield strength (n / mm2) ≥ 205

Tensile strength ≥ 520

Elongation (%) ≥ 40

Hardness HB ≤ 187 HRB ≤ 90 HV ≤ 200

The stainless steel rods

The stainless steel rods

The density was 7.93 g · cm-3

Specific heat C (20 ℃) 0.502 J · (g · C) – 1

Thermal conductivity λ / w (m ·℃) – 1 (at the following temperature / ℃)

20 100 500

12.1 16.3 21.4

Linear expansion coefficient α / (10-6 / ℃) (between the following temperatures / ℃)

20~100 20~200 20~300 20~400

16.0 16.8 17.5 18.1

The resistivity is 0.73 Ω· mm2 · M-1

Melting point 1398 ~ 1420 ℃

| Grade |

ASME SA240 304 Mechanical Strength |

||||

|

Yield |

Tensile |

Elongation |

Hardness, max |

||

|

A240 304L |

Min Mpa |

Mpa |

Min % |

Brinell |

Rockwell B |

|

205 |

515 |

40% |

201 |

92 |

|

|

|

|

|

|

|

|

|

Plate Grade |

The Element Maximum (%) |

||||||

|

C |

Mn |

P |

S |

Si |

Cr |

Ni |

|

|

ASTM A240 304L |

0.03 |

2.00 |

0.045 |

0.030 |

0.75 |

18.0-20.0 |

8.0-10.5 |

|

Mo |

N |

Cu |

|

|

|

|

|

|

|

0.10 |

|

|

|

|

|

|

- What is astm a240 304l density?

|

Steel Grade |

Density(g/cm3) |

|

304,304L,305,321 |

7.93 |

|

316,316L,347 |

7.98 |

|

405,410,420 |

7.75 |

|

409,430,434 |

7.7 |

What is astm a240 specification other grade?

- 304 is a kind of universal stainless steel, which is widely used to make equipment and parts with good comprehensive performance (corrosion resistance and formability).

- 301 stainless steel presents obvious work hardening phenomenon during deformation, which is used in various occasions requiring higher strength.

- 302 stainless steel is essentially a variety of 304 stainless steel with higher carbon content, which can obtain higher strength by cold rolling.

- 302B is a kind of stainless steel with high silicon content, which has high oxidation resistance at high temperature.

- 303se and 303se are free cutting stainless steels containing sulfur and selenium respectively, which are mainly used in the occasions requiring easy cutting and high surface finish. 303se stainless steel is also used to make machine parts requiring hot upsetting because it has good hot workability under such conditions.

- 304L is a variant of 304 stainless steel with low carbon content, which is used for welding. The lower carbon content makes the carbides precipitated in the heat affected zone near the weld to a minimum, and the precipitation of carbides may cause intergranular corrosion (welding corrosion) of stainless steel in some environments.

- 304n is a kind of stainless-steel containing nitrogen. The purpose of adding nitrogen is to improve the strength of steel.

- 305 and 384 stainless steels contain high nickel, and their work hardening rate is low, so they are suitable for various occasions with high requirements for cold formability.

- 308 stainless steel is used for welding rod.

- The contents of Ni and Cr in 309, 310, 314 and 330 stainless steels are relatively high in order to improve the oxidation resistance and creep strength of the steels at high temperature. However, 309S and 310S are variants of 309 and 310 stainless steels, but the difference is that the carbon content is low, so as to minimize the carbide precipitated near the weld. 330 stainless steel has high carburizing resistance and thermal shock resistance

- Type 316 and 317 stainless steels contain molybdenum, so their pitting corrosion resistance in marine and chemical industry environments is much better than that of 304 stainless steel. Among them, type 316 stainless steel includes low carbon stainless steel 316L and high strength stainless steel containing nitrogen.

- 316N and 316F, a free cutting stainless steel with high sulfur content.

- 321, 347 and 348 are stainless steels stabilized with titanium, niobium plus tantalum and niobium respectively. They are suitable for welding at high temperature. 348 is a kind of stainless steel which is suitable for nuclear power industry.

- The forging property of 304L stainless steel is poor and the deformation is difficult.

Supply ASTM A240, 304L, 316LN, 316H, 316Ti, 309S, 310S stainless steel

1. Steel Grade: A240 TP201, TP202, TP304L, TP309S, TP310S, TP316L, TP321, TP405, TP430, TP630, 2205, 2507

2. Available Size: thickness: 1-100mm, width: 500-2500mm, length: 1000-6000mm

3. Delivery Condition: No.1, No.2D, No.2B

4. Delivery Time: 3 days

5. Payment Item: TT or L/C

6. Trade Terms: FOB, CFR or CIF

7. Inspection: MTC, TPI (ABS, BV, LR, TUV, SGS), PMI Test.

If you need ASTM A240, TP304, TP316L, TP316H TP316Ti, TP309S stainless steel, please contact us freely. - Aesteiron Steels is a very properly recognised and well-liked provider of 304L stainless Steel in most of the meals and dairy industries in India, Philippines, Malaysia, Indonesia, Singapore, Thailand, Qatar and few countries in Europe and west Africa.

- Nr. 1.4307 alloy comes within the class of Austenitic Stainless Steel which offers good power on excessive temperature as nicely corrosion resistance to sulphuric acid.

- 304L Stainless Plate is a perfect and economical metal plate to make chemical storage containers and milk tankers.

- If you’re in search of Jindal make 304L chrome steel coil Aesteiron steels can provide 2-3% lesser worth than sellers and distributors of Jindal stainless in Mumbai provide to the purchasers.

ASTM A240 304L stainless steel plate thermal expansion coefficient Manufacturer

304 stainless-steel plate is comprised of no more than 0.08% carbon whereas 304L stainless steel plate incorporates a maximum of 0.03% carbon. The other major difference in chemical composition between these two stainless-steel plates grades is the amount of nickel.

The low carbon offers resistance to sensitization throughout welding and other thermal processes. These 317 / 317L Stainless Steel Sheets & Plates confirms confrontation to sensitization in the course of fusing or when thermal procedures are useful due to the low content of carbon in its chemical configuration. For supreme erosion confrontation in these 317L Stainless Steel Plates, forgings should be hardened at 1900 Deg F smallest as potential A240 SS304L steel plate MILL and water satiated or quickly cooled by another sources after hot functioning processes. Alloy 304L a T-300 sequence stainless-steel austenitic, which has a minimal of 18% chromium and 8% nickel. It is the standard “18/eight stainless” that is commonly present in pans and cooking tools.

Relative keywords: 304l|304l stainless steel|aisi 304l|chemical composition of ss 304|sus 304l|composition of ss 304|ss304l|1.4307 stainless steel|304l stainless steel properties|ss 304 material properties|1.4307 material|304l steel|sa 240 gr 304|1.4306 material|304l chemical composition|ss 304l chemical composition|304l ss|304l stainless steel composition|sa 240 304l|astm a312 tp304l|yield strength 304|304l composition|uns s30403|304 stainless composition|304 stainless yield strength|ss 304 tensile strength|material 304l|1.4307 steel|s30403|aisi 304l stainless steel|sa 479 304|ss304l composition|1.4306 stainless steel|astm 304l|sa 240 type 304|ss 304 material composition|304l stainless steel price|astm a240 304l|ss304l properties|1.4307 chemical composition|sa312 tp304l|

What is the difference between 304 and 304l stainless steel?

The difference between 304 and 304L stainless steel is that 304L has a . 03 max carbon and is good for welding whereas 304 has a mid range level of carbon.

Only sheltered areas need occasional washing with a stream of pressurized water. In heavy industrial areas, frequent washing is advisable to remove filth deposits which could ultimately cause corrosion and impair the surface appearance of the stainless steel. A temperature gradient is produced in the material being welded which ranges from above the melting temperature within the molten pool to ambient temperature at far from the weld. The higher the carbon degree of the fabric being welded, the larger the chance that the welding thermal cycle will outcome in the chromium carbide precipitation which is detrimental to corrosion resistance. To provide materials at the best level of corrosion resistance, low carbon material should be used for material put in service within the welded condition. Alternately, full annealing dissolves the chromium carbide and restores a excessive stage of corrosion resistance to the standard carbon content supplies. The austenitic stainless steels are considered to be the most weldable of the excessive-alloy steels and can be welded by all fusion and resistance welding processes.

304L Stainless Steel Sheet is used almost completely for components requiring machining, welding, grinding, or sharpening where good corrosion resistance can be required. Good in corrosive environments as in paper and chemical industries and cryogenic providers. Used where corrosion resistance and good mechanical properties are main requirements. 304/304L is extensively accepted in such industries as dairy, beverage, and different meals industries the place the highest diploma of sanitation and cleanliness is of prime significance.

astm a240 304l chemical composition

SS 304 plates perform as non-magnetic materials in annealed situations and appropriate alloy to make nut- bolts for pumps and motors. Aesteiron steels carry the ASTM a240 tp 304L plates and coils in bulk amount from the highest rolling mills in India, South Korea and Japan. If you’re in search of Jindal make 304L stainless-steel coil Aesteiron steels can provide 2-3% lesser value than sellers and distributors of Jindal stainless in Mumbai provide to the purchasers. Type 304L can be utilized in domestic applications specifically in houses close to sea so it helps to resist corrosion in moisture and salty local weather. Aesteiron Steels is called a one of the largest stockist and supplier of Stainless metal Sheets and Plates we inventory over 800 ton stock in grades like 304/ 304L/ 316/ 316L/ 310/ 321/ 317L and 904L. These SS 304 / 304L Sheets Plates are manufactured through the cold rolling course of and embrace ASTM A240 standard. The thickness of these sheets and plates varies from 0.4mm to 6.0mm and width is 1000mm, 1500mm and extra as per the demand of shoppers.

ASTM A240 304L stainless steel plate wiki Manufacturer

Choosing the Best Stainless Steel Work Tables – South Florida Reporter

Choosing the Best Stainless Steel Work Tables.

Posted: Mon, 02 Nov 2020 21:23:00 GMT [source]

Alloy 304L is most well-liked to be used in environments sufficiently corrosive to trigger intergranular corrosion of welds and warmth-affected zones on prone alloys. At instances, alloy 304L could present a decrease corrosion fee than the higher carbon Alloy 304; otherwise, the 304, 304L, and 304H could also be thought of to perform uniformly in most corrosive environments. Resistance to corrosion in oxidizing environments is a result of the 18 to 19% chromium that the 304 alloys include. For materials uncovered inland, light industrial, or milder service, minimum maintenance is required.

We carry out numerous checks in any respect phases of production, right from the procurement of uncooked materials to the final delivery. The checks which have been performed include PMI Test, Pitting Resistance Test, Flaring Test, Intergranular Corrosion Test, Hardness Test, Chemical Analysis, Micro and Macro Test, and so on.

astm a240 304l,astm a240 type 304l,a240 304l material cutting parts,a240-304 machine parts,a240 304 flat bar ,sa240 304l welded pipe,a240 grade 304 seamless pipe,a240-304l waterjet cutting disc,a240-304 material,a240 tp304l laser cutting parts,astm a240 304l mechanical properties,astm a240 304l chemical composition,astm a240 304l properties,a240 gr 304l Origin China,sa240 tp 304l angle bar,a240 type 304l square pipe,sa240 type 304l angle steel mill,astm a240 304l stainless steel,astm a240 304l density,astm a240 304l specification,a240 tp 304l in 7days delivery time,astm a240 304l plate,a240 304l material stock list,astm a240 grade 304l,astm a240 gr 304l stocklist thick 5-300mm,astm a240 304l yield strength,ASTM A240 304L stainless Manufacturer,ASTM A240 304L stainless steel plate Manufacturer,