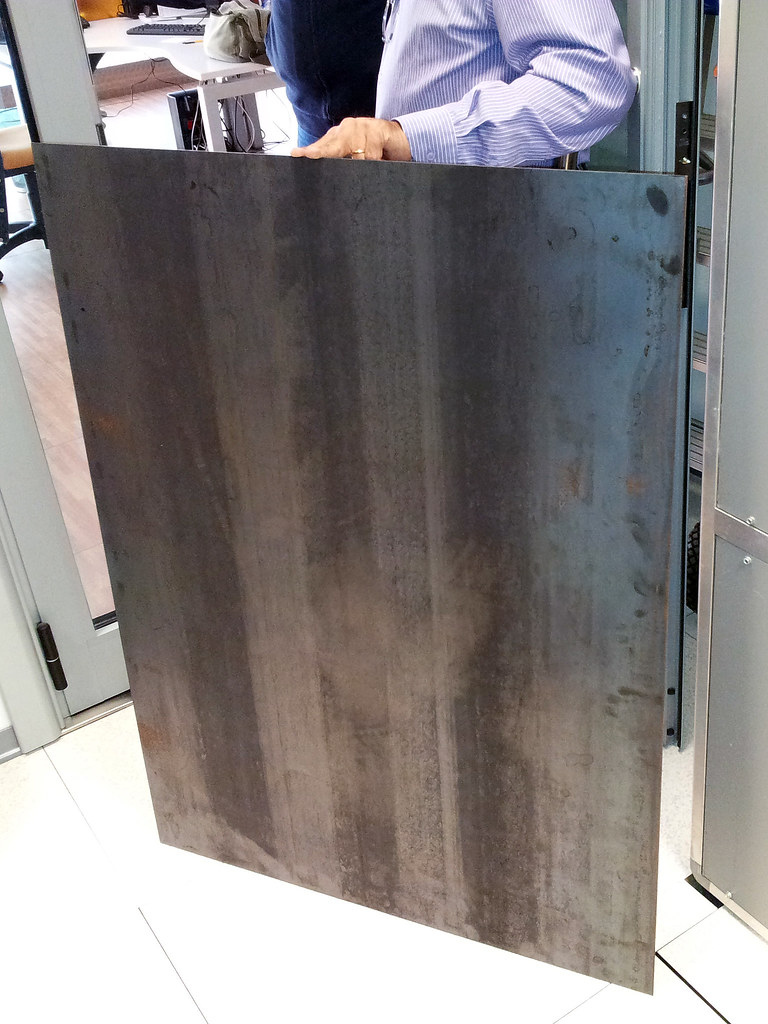

EN 10025-6 S620Q strength quenched and tempered steel

Gangsteel produce and supply materials of EN10025-6 S620q steel plate and equal grade S590Q, S690Q, S690QL, S690QL1, WQ690D, Q550D, WQ590D, WH70Q, WDB620E, WH785E S620q steel plate Executive standard: EN10025-6, GB/T16270-2009.

EN10025-6 S620q Alloy special steel with specified minimum values of impact energy at temperatures not lower than -20 degree .

Chemical composition of steel S620Q (1.8914), Standards of steel S620Q (1.8914) and Mechanical Properties of steel S620Q (1.8914) Equivalent grades of steel S620Q (1.8914)

about the steel S620Q (1.8914) Tensile Strength, Elongation, Proof strength , Hardness, please see our table.

This covers plates for fastened and cellular offshore structures and contains both normalised and thermomechanical offshore steels. Minimum values of impression energy for influence exams on transverse V-notch take a look at pieces for quenched and tempered metal, when the influence test on transverse check pieces is agreed on the time of the order. That contains verifying the chemical composition of the delivered base steel, figuring out its weldability, deciding on the type of eventual warmth therapy and then checking that the executed welded joints possess the required mechanical and metallurgical properties. We are Manufacturer and Exporter of S690QL Structural Steel Plate, EN S690QL High Yield Steel Plates Suppliers in Mumbai, India. All of our S690 QL EN 10025–6 structural metal Plates, EN10025 S690QL High Tensile Plate, is made and tried to worldwide tips, and specs as per ASME, ANSI & ASTM, etc. The analysis accommodates casting with out elektromagnetic area and a number of other sequence of casting under the affect of electromagnetic fields with completely completely different operating parameters.

S690ql Metal Plate Value, 2020 S690ql Metal Plate Price ..

Problems of reparatory welding of the broken mandrel axle-shaft are thought of on this paper. After visual inspecting of the damaged half and analysis of the crack position and static and dynamic loads, which brought on the fracture, it was estimated that the damaged part could possibly be repaired, however by a really complicated welding procedure mixed with heat remedy. The axle-shaft was successfully repaired and the spinner was capable of operating. The downtime was significantly decreased and the costs of procuring/manufacturing the brand new part prevented.

- DIN EN S690QL Non- Alloy Structural Steel Plate TJC Steel can provide DIN EN S690QL Structural Carbon Steel Plate, primarily utilized in construction within the fields requiring carbon steel plates with kinds of impression exams and strength.

- Zhang et al. researched the microstructures and mechanical properties of weld-repaired HSLA steel.

- The peak temperatures reached inside the softest HAZ had been between Ac1 and Ac3 (730–870 °C on this case).

- The hardness of the bottom materials ranged between 224 and 264 HV, whereas the hardness of the softest zone of the heat affected zone was roughly one hundred fifty HV , emphasizing an enormous mismatch when evaluating BM hardness to the minimum HAZ hardness.

The temperature cycles had been measured and then the obtained values for the important cooling time t8/5 have been entered into the CCT diagrams to estimate the hardness and microstructure of the welded joint’s zones. Experiments had been conducted on the multi-layered hard-confronted samples made from the steel for manufacturing of the forging dies. The examine evaluates numerically and experimentally the effect of welding heat enter parameters on the microstructure and hardness of the warmth-affected zone of quenched and tempered and thermo-mechanically controlled course of 690-MPa high-energy steel. Numerical analyses and experimental comparisons have been applied using three warmth input values (10, 14, and 17 kJ/cm) so as to predict the thermal fields throughout welding. Experimental analysis was carried out of the microstructure and microhardness behavior in different HAZ areas.

- What is EN 10025-6 S620Q steel plat?

EN10025-6 S620Q steel plate is EN 1.8914, Alloy special steel with specified minimum values of impact energy at temperatures not lower than -20 ° C. The main adopt standard are EN 10025-6: 2004 Hot rolled products of structural steels. Technical delivery conditions for flat products of high yield strength structural steels in the quenched and tempered condition

EN 10137-2: 1996 S620Q Plates and wide flats made of high yield strength structural steels in the quenched and tempered or precipitation hardened conditions. Delivery conditions for quenched and tempered steels

- What is EN 10025-6 S620Q OR 1.8914 Chemical composition % of steel EN 10025-6 S620Q (1.8914): EN 10025-6-2004

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

V |

N |

Nb |

Ti |

Cu |

Zr |

B |

CEV |

|

max 0.2 |

max 0.8 |

max 1.7 |

max 2 |

max 0.025 |

max 0.015 |

max 1.5 |

max 0.7 |

max 0.12 |

max 0.015 |

max 0.06 |

max 0.05 |

max 0.5 |

max 0.15 |

max 0.005 |

max 0.83 |

- What is Mechanical properties of steel EN 10025-6 S620Q (1.8914)?

|

Nominal thickness (mm): |

3 – 100 |

100 – 150 |

|

Rm – Tensile strength (MPa) |

700-890 |

650-830 |

- What is Equivalent grades of steel EN10025-6 S620Q (1.8914)

|

EU |

Germany |

France |

European old |

|||

|

S620Q |

|

|

|

|

EN10025-6 EQUAL Grade stock list in China warehouse |

|||||||

|

|

Grade |

size mm |

Thick mm |

Wide mm |

Long mm |

Tons |

Quantity |

|

High-strength structural stee plate |

BS960E |

7*1600*11300 |

7 |

1600 |

11300 |

2.023 |

2 |

|

|

Q550CFD |

16*2500*12000 |

16 |

2500 |

12000 |

3.768 |

1 |

|

|

Q550CFD |

16*2500*12000 |

16 |

2500 |

12000 |

3.768 |

1 |

|

|

Q550CFD |

20*2500*12000 |

20 |

2500 |

12000 |

4.71 |

1 |

|

|

Q550CFD |

20*2500*12000 |

20 |

2500 |

12000 |

4.71 |

1 |

|

|

Q550CFD |

20*2500*12000 |

20 |

2500 |

12000 |

4.71 |

1 |

|

|

Q550CFD |

36*2500*9500 |

36 |

2500 |

9500 |

6.712 |

1 |

|

|

Q550CFD |

36*2500*9500 |

36 |

2500 |

9500 |

6.712 |

1 |

|

|

Q550CFD |

36*2500*9500 |

36 |

2500 |

9500 |

6.712 |

1 |

|

|

Q550CFD |

36*2500*9500 |

36 |

2500 |

9500 |

6.712 |

1 |

|

|

Q690CFD |

30*2550*10640 |

30 |

2550 |

10640 |

6.39 |

1 |

|

|

SC960E |

30*1550*5800 |

30 |

1550 |

5800 |

2.117 |

1 |

|

|

NQB-S690QL |

20*1700*11000 |

20 |

1700 |

11000 |

2.936 |

1 |

|

|

BS700MCK2 |

8*1500*13000 |

8 |

1500 |

13000 |

1.227 |

1 |

|

|

BWELDY620QL6 |

12*2400*6220 |

12 |

2400 |

6220 |

1.406 |

1 |

|

|

BWELDY620QL6 |

12*2400*9000 |

12 |

2400 |

9000 |

2.035 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

4.239 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

4.71 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

5.181 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

4.71 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

4.71 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

1.884 |

4 |

|

|

BS700MCK2 |

10*1500*6000 |

10 |

1500 |

6000 |

2.12 |

1 |

|

|

BS700MCK2 |

10*1500*6000 |

10 |

1500 |

6000 |

0.707 |

1 |

|

|

BS700MCK2 |

10*1500*6000 |

10 |

1500 |

6000 |

0.706 |

1 |

|

|

BS700MCK2 |

12*1500*12000 |

12 |

1500 |

12000 |

3.391 |

2 |

|

|

BS700MCK2 |

12*1500*12000 |

12 |

1500 |

12000 |

3.391 |

1 |

|

|

BS700MCK2 |

12*1500*12000 |

12 |

1500 |

12000 |

3.391 |

1 |

|

|

BS700MCK2 |

12*1500*13000 |

12 |

1500 |

13000 |

1.837 |

1 |

|

|

BS700MCK2 |

12*1500*4000 |

12 |

1500 |

4000 |

1.696 |

1 |

|

|

BS700MCK2 |

12*1500*4000 |

12 |

1500 |

4000 |

4.522 |

1 |

|

|

BS700MCK2 |

12*1500*4000 |

12 |

1500 |

4000 |

4.522 |

1 |

7. Obtained German TUV certification.

S620Q steel plate uses: used to manufacture low-temperature resistant, high-strength key components, construction machinery, mining machinery structures, etc. It is a high-strength structural steel plate.

European elevation strength alloy steel plate: S460Q, S460QL, S460QL1, S500Q, S500QL, S500QL1, S550Q, S550QL, S550QL1, S590Q, S620Q, S620QL, S620QL1, S690Q, S690QL, S690QL1, S890Q, S890QL, S890QL1, S960Q, S960QQL, S960QQL1,

WQ690D, Q550D, WQ590D, WH70Q, WDB620E, WH785E, etc.;

In the circumstances of the overmatched welded joints containing a soft root layer it’s attainable to attain a comparable fracture behaviour related to the homogeneous overmatched welded joint if the impact toughness of the delicate root layer is greater than the impression toughness of the overmatched weld steel. Such a type of welded joint is due to this fact preferable for the welding of excessive strength low alloy steels, because it allows the manufacturing of a welded joint without preheating. High energy steels belong into a group of top of the range steels, with exceptional mechanical properties, especially in regards to tensile power. At the identical time, as their deficiency is emphasized the restricted and difficult weldability. In different words, a few of these steels are weldable solely with application of particular measures associated to controlled heat input.

EN 10025-6 S620Q strength steel bolt material

Equivalent grades of steel S620Q (1.8914)Equivalent grades of steel S620Q (1.8914)Heat treatment conditions+A Soft annealed+AC Annealed to achieve spheroidization of the carbides+AR As rolled+AT Solution annealed+C Cold drawn / hard+CR Cold rolled+FP Treated to ferrite-pearlite structure and hardness range+I Isothermal annealing+LC Cold drawn / soft+M Thermo mechanical rolling+N Normalized+NT Normalized and tempered+P Precipitation hardened+PE Peeled+QA Air quenched and tempered+QL Liquid quenched and tempered+QT Quenched and tempered+S Treated to improve shearability+SH As rolled and turned+SR Cold drawn and stress relieved+T Tempered+TH Treated to hardness range+WW Warm worked+U Untreated

When the metallurgy problems had been solved and the optimum brazing parameters chosen, the optimal mechanical properties have been achieved, which had been experimentally confirmed. S690Q is a scorching-rolled hardened structural metal that has undergone subsequent tempering treatment and conforms to the EN , DSTU EN commonplace. Depending on the thickness of the product and the manufacturing situations, the producer could add to the steel one or several alloying components up to the maximum values given so as to get hold of the desired properties.

S355 structural grade carries minimal yield strength of 355 N/mm²m, the JR designation confirms that the link for you metal has undergone longitudinal Chary V-Notch influence testing at 27J at room temperature. In the desk of European requirements for metallic materials, specs for seamless and welded steel pipes and pipes products EN10025-6 S620Q steel plate supplier, wire and wire products, forgings, sheets, strips and definition of metal products are introduced. Whilst EN10204 describes the type of materials check certificates that should accompany metal plates, this describes what has to enter the certificates.

S355J2WP steel is a scorching rolled structural steel with anti-corrosion feature, also referred to as weathering metal and ambiance corrosion resistance steel, under commonplace EN . S620Q, S620QL, S620QL1 Plates have larger payload capability and are energy environment friendly, hence can be used in leaner constructions. This steel is used in different functions such as heavy transportation, construction business, machine building, and lifting tools. We ship products in customizable options to meet buyer-specified necessities. The trendy excessive power metal plates have an excellent combination of energy and toughness primarily based totally on micro-alloying and sophisticated microstructure. Retaining this mix of properties within the weld zone is a significant drawback for functions in excessive-demanding structural improvement.

INOX B 18/eight/6, mark EN 18 eight Mn B 22 according to EN 1600–Applied as interlayers for application of the muse welds aimed to lower the residual stresses and improve the weld plasticity and toughness. Hence, intercritically reheated and tempered areas type and these regions could have utterly totally different mechanical properties than unaltered HAZ areas. From the record of supplies, you can review detailed properties and equivalents of every material. By merely clicking the materials sizzling link, you can see a listing of metal materials defined by the chosen commonplace.

The numerical values indicate that the maximum respective values of temperature measured in QT steel and TMCP metal have been about 1300 and 1200 °C for a heat enter of 10 kJ/cm, 1400 and 1300 °C for a warmth input of 14 kJ/cm, and 1600 and 1450 °C for a warmth input of 17 kJ/cm. The cooling times resulted, for a heat input of 10 kJ/cm, in numerical t8/5 (14.5 s) and experimental (18.84 s) increases in hardness within the coarse-grain warmth-affected zone of the QT steel (317 HV0.1), due to the formation of bainite and lath martensite buildings with grain growth. Decreased hardness in the CGHAZ of TMCP steel (240 HV0.1) was brought on by primary recrystallization of the microstructure and the formation of more equilibrium products of austenite decomposition. Increasing the heat enter (14 to 17 kJ/cm) led to numerical t8/5 and experimental decreases in hardness within the CGHAZ of QT steel (270 HV0.1) due to the full austenite , and maintained the relative value of TMCP steel (235 HV0.1). This paper presents analysis of the influence toughness and hardness distribution in particular zones of a ‘single V’butt multiple-pass welded joints of the high-power low-alloyed steels. Obtained values of the influence toughness are analyzed in correlation with a microstructure in particular zones of the welded joint, together with the micro hardness distribution discovered in the related zones. Based on the carried out analysis and results obtained in experiments, the applied expertise of welding was evaluated.