A240 a203gr.a metal 15pc knife block

The tensile power of an alloy is mostly measured by inserting a test piece in the jaws of a tensile machine. The tensile machine applies stretching stress by gradually separating the jaws.

AISI utilises a four-digit numbering system for carbon steels and a three-digit numbering system for stainless steels, having a “kind” prefix for identification. Some metal grades include suffixes that indicate the modifications within the composition, corresponding to type 303Se, displaying the addition of selenium into the composition.

The AISI compositions and designations act as the first standards for a wide range of industries . The time period tensile energy refers back to the amount of tensile (stretching) stress a material can stand up to earlier than breaking or failing. Tensile energy is a crucial measure of a fabric’s ability to perform in an application, and the measurement is extensively used when describing the properties of metals and alloys. Grade A steel plate is used for shipbuiling’s hull construction and platform.

A240 a203gr.a steel 15pc knife block

This oxide layer resists corrosion, while on the similar time prevents oxygen from reaching the underlying steel. Other components in the alloy, corresponding to nickel and molybdenum, add to its rust-resistance. I suppose your best wager is to easily purchase high-quality stainless-steel from the beginning, from a brand with a reputation for good high quality. But, I suppose I even have discovered a method that you could determine if the stainless cookware you have already got is potentially reactive. Tin (Sn) was first used as an alloying factor with copper to kind bronze.

What grade is normal mild steel?

Mild Steel Grade 250 Grade 250 Mild Steel is a medium strength structural steel plate product with nominal yield strength of 250 MPa. Typical uses include: General Fabrication.

All testing strategies for engineering metals and alloys are coated by ASTM materials specification requirements. Each material specification for a metal alloy includes the final word tensile power of steel, plus its yield, elongation and discount ASTM A203GR.A Nickel-Alloy steel plate of area values. AISI is the most well-liked and the oldest numbering system for all steels in the US. It states the chemical composition of an alloy based mostly on ladle evaluation but does not point out other properties.

A240 a203gr.a metal third rack

- All testing strategies for engineering metals and alloys are lined by ASTM material specification requirements.

- Each materials specification for a metallic alloy consists of the ultimate tensile energy of metal, plus its yield, elongation and reduction of space values.

- AISI is the preferred and the oldest numbering system for all steels in the US.

- It states the chemical composition of an alloy based mostly on ladle analysis but doesn’t indicate other properties.

Corrosion resistance, heat resistance, weldability and machinability are other properties that come into play within the number of a metallic or alloy for a selected utility. Before you utilize a steel plate in an engineering or development utility, you should determine its power to ensure it could possibly carry the masses being utilized to it. One of the commonest energy exams is the final word tensile strength take a look at, which determines the utmost stress a cloth can withstand without breaking. Once you’ve got measured the maximum stress, deriving the last word power worth of a metal plate is easy.

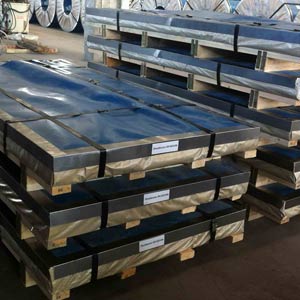

China United Iron and steel Limited export ASTM A203/A203M Nickel-Alloy steel plate of A203GR.A,ASTM A203GR.A,A203GR.A Steel,A203GR.A HIC,A203GR.A NACE. If you have inquiry for that, please contact us by admin@corten-asteel.com

A240 a203gr.a steel plate 4×8

The shipbuilding steel plate grade A is the common tensile strength steel. The reversal point is the maximum stress on the engineering stress–pressure curve, and the engineering stress coordinate of this point is the last word tensile strength, given by point 1. We’ll deal right here with the properties most related to engineering metals and alloys, particularly their yield strength (Y.S.) tensile strength (U.T.S.), elongation (EL%) and reduction of area (R.O.A.%). We choose metals for his or her many applications based on numerous properties. Metals have to be very sturdy in some instances, comparatively gentle and ductile in others.

Tin is a soft metallic with shiny silver color and is very corrosion resistant in air and water. Tin’s corrosion resistance helps it serve in bronze and pewter alloys, as a durable element of electrical solder, and as protective plating for different metals. Steels are impure iron-carbon alloys of low carbon content, often 0.1–1.5% carbon by weight. The amount of carbon and level of impurities and additional components, each metallic and non-metallic, determine the properties of every steel grade .

A240 a203gr.a steel plate 50mm

When talking about heavy metals, you have to distinguish between density and atomic weight. Density is measured in kilograms per cubic meter (kg/m3) or grams per cubic cm (g/cm3). Stainless metal varieties, corresponding to 304 or 316, are a mix of parts, and most include some quantity of iron, which easily oxidizes to form rust. But many stainless steel alloys also comprise a high percentage of chromium – a minimum of 18 percent – which is much more reactive than iron. The chromium oxidizes shortly to form a protecting layer of chromium oxide on the metallic surface.