ASTM A240 304L stainless steel plate welding rod Manufacturer

Content

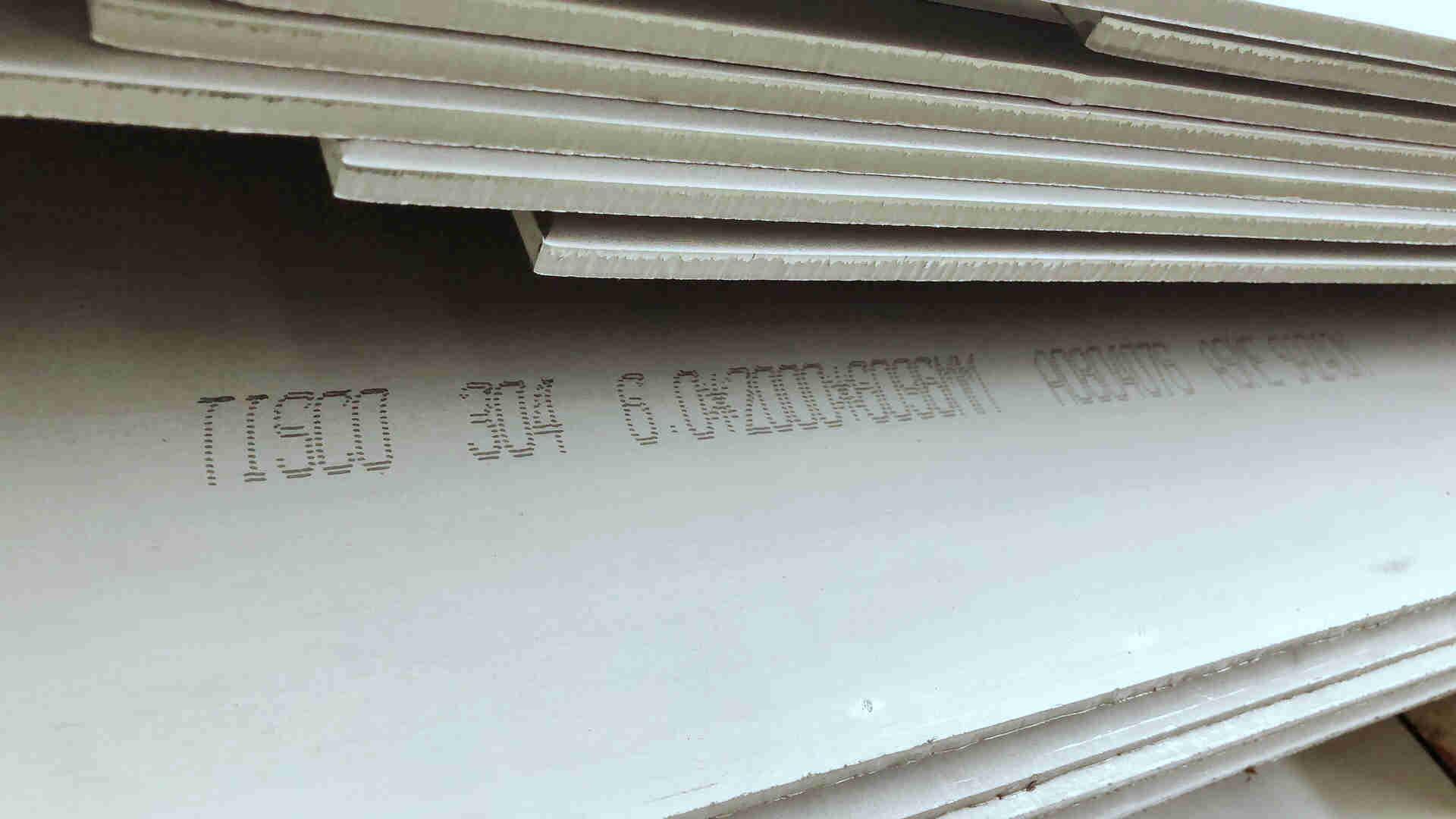

gangsteel supply astm a240 304l Stainless steel plate thickness 1mm to 300mm. the max width 2800mm. We also provide laserjet and water jet cutting for stainless grade astm a240 304l,astm a240 type 304l.a240 304l material cutting parts,a240-304 machine parts,a240 304 flat bar ,sa240 304l welded pipe.

a240 grade 304 seamless pipe,a240-304l waterjet cutting disc,a240-304 material,a240 tp304l laser cutting parts,astm a240 304l mechanical properties,astm a240 304l chemical composition,astm a240 304l properties,a240,gr 304l Origin China,sa240 tp 304l angle bar,a240 type 304l square pipe,sa240 type 304l angle steel mill,astm a240 304l stainless steel,astm a240 304l density,astm a240 304l specification.

It has higher mechanical properties and localized corrosion resistance compared to sort 316L alloy. Austenitic stainless steels have an fcc (γ) construction, until they endure a part transformation due to severe plastic deformation. Chromium soluted evenly within the microstructure allows the formation of a skinny (typically 10–50 Å thick), amorphous chromium oxide layer on high of the steel. The ionic bonding on this layer protects the surface from electrochemical degradation. Hence, stainless steels are sometimes pickled in nitric acid to reinforce the expansion and thickening of this passive layer.

ASTM 304 A240 304L stainless steel plate properties Manufacturer

- A passive metallic usually exhibits a higher electrode potential than one which is present process lively dissolution.

- Solutions with a lower ph than 7 are mentioned to be acidic, and options with the next ph are said to be alkaline.

- Metallic biomaterials characterize the class of supplies with the largest use in medical units in humans at present.

- Passive layer The chromium oxide layer on the stainless steel surface that protects the steel from being attacked by corrosion.

- These biomaterials embrace stainless steels, cobalt-chromium alloys, titanium and its alloys, Nitinol form reminiscence alloy, dental amalgams, gold, metallic glasses and biodegradable metals.

These authors instructed that this was as a result of low dissolved oxygen concentration in physique fluids. Piehler et al. examined hip nail plates and found that enormous plates had higher CF resistance than small ones and that Ti–6Al–4V carried out better than 316L chrome steel.

- What is ASTM A240 304L Stainless steel grade?

304L stainless steel is a universal stainless-steel material.

Grade of 304L stainless steel:

The old standard JB / T 4237-1992 corresponds to 00Cr19Ni10

New standard GB / T 20878-2007 grade and chemical composition of stainless steel and heat resistant steel

And GB 24511 2009 stainless steel plate and strip for pressure equipment

Corresponding to 022cr19ni10, its carbon content is about 0.03%

The unified digital code s30403 is different from s30408 of 304

- What is Stainless steel ASTM a240 304l chemical composition and astm a240 304l mechanical properties?

Analysis of chemical composition% of 304L stainless steel

Carbon C: ≤ 0.03,

Silicon Si: ≤ 1.0,

Mn: ≤ 2.0,

Cr: 18.0-20.0,

Ni: 9.0-12.0,

Sulfur s: ≤ 0.03,

Phosphorus P: ≤ 0.045;

mechanical property

The mechanical properties of 304L stainless steel are as follows

Yield strength (n / mm2) ≥ 205

Tensile strength ≥ 520

Elongation (%) ≥ 40

Hardness HB ≤ 187 HRB ≤ 90 HV ≤ 200

The stainless steel rods

The stainless steel rods

The density was 7.93 g · cm-3

Specific heat C (20 ℃) 0.502 J · (g · C) – 1

Thermal conductivity λ / w (m ·℃) – 1 (at the following temperature / ℃)

20 100 500

12.1 16.3 21.4

Linear expansion coefficient α / (10-6 / ℃) (between the following temperatures / ℃)

20~100 20~200 20~300 20~400

16.0 16.8 17.5 18.1

The resistivity is 0.73 Ω· mm2 · M-1

Melting point 1398 ~ 1420 ℃

| Grade |

ASME SA240 304 Mechanical Strength |

||||

|

Yield |

Tensile |

Elongation |

Hardness, max |

||

|

A240 304L |

Min Mpa |

Mpa |

Min % |

Brinell |

Rockwell B |

|

205 |

515 |

40% |

201 |

92 |

|

|

|

|

|

|

|

|

|

Plate Grade |

The Element Maximum (%) |

||||||

|

C |

Mn |

P |

S |

Si |

Cr |

Ni |

|

|

ASTM A240 304L |

0.03 |

2.00 |

0.045 |

0.030 |

0.75 |

18.0-20.0 |

8.0-10.5 |

|

Mo |

N |

Cu |

|

|

|

|

|

|

|

0.10 |

|

|

|

|

|

|

- What is astm a240 304l density?

|

Steel Grade |

Density(g/cm3) |

|

304,304L,305,321 |

7.93 |

|

316,316L,347 |

7.98 |

|

405,410,420 |

7.75 |

|

409,430,434 |

7.7 |

What is astm a240 specification other grade?

- 304 is a kind of universal stainless steel, which is widely used to make equipment and parts with good comprehensive performance (corrosion resistance and formability).

- 301 stainless steel presents obvious work hardening phenomenon during deformation, which is used in various occasions requiring higher strength.

- 302 stainless steel is essentially a variety of 304 stainless steel with higher carbon content, which can obtain higher strength by cold rolling.

- 302B is a kind of stainless steel with high silicon content, which has high oxidation resistance at high temperature.

- 303se and 303se are free cutting stainless steels containing sulfur and selenium respectively, which are mainly used in the occasions requiring easy cutting and high surface finish. 303se stainless steel is also used to make machine parts requiring hot upsetting because it has good hot workability under such conditions.

- 304L is a variant of 304 stainless steel with low carbon content, which is used for welding. The lower carbon content makes the carbides precipitated in the heat affected zone near the weld to a minimum, and the precipitation of carbides may cause intergranular corrosion (welding corrosion) of stainless steel in some environments.

- 304n is a kind of stainless-steel containing nitrogen. The purpose of adding nitrogen is to improve the strength of steel.

- 305 and 384 stainless steels contain high nickel, and their work hardening rate is low, so they are suitable for various occasions with high requirements for cold formability.

- 308 stainless steel is used for welding rod.

- The contents of Ni and Cr in 309, 310, 314 and 330 stainless steels are relatively high in order to improve the oxidation resistance and creep strength of the steels at high temperature. However, 309S and 310S are variants of 309 and 310 stainless steels, but the difference is that the carbon content is low, so as to minimize the carbide precipitated near the weld. 330 stainless steel has high carburizing resistance and thermal shock resistance

- Type 316 and 317 stainless steels contain molybdenum, so their pitting corrosion resistance in marine and chemical industry environments is much better than that of 304 stainless steel. Among them, type 316 stainless steel includes low carbon stainless steel 316L and high strength stainless steel containing nitrogen.

- 316N and 316F, a free cutting stainless steel with high sulfur content.

- 321, 347 and 348 are stainless steels stabilized with titanium, niobium plus tantalum and niobium respectively. They are suitable for welding at high temperature. 348 is a kind of stainless steel which is suitable for nuclear power industry.

- The forging property of 304L stainless steel is poor and the deformation is difficult.

Supply ASTM A240, 304L, 316LN, 316H, 316Ti, 309S, 310S stainless steel

1. Steel Grade: A240 TP201, TP202, TP304L, TP309S, TP310S, TP316L, TP321, TP405, TP430, TP630, 2205, 2507

2. Available Size: thickness: 1-100mm, width: 500-2500mm, length: 1000-6000mm

3. Delivery Condition: No.1, No.2D, No.2B

4. Delivery Time: 3 days

5. Payment Item: TT or L/C

6. Trade Terms: FOB, CFR or CIF

7. Inspection: MTC, TPI (ABS, BV, LR, TUV, SGS), PMI Test.

If you need ASTM A240, TP304, TP316L, TP316H TP316Ti, TP309S stainless steel, please contact us freely.

Vanadium metal was developed in the early 1900s specifically for implants . Its first application was bone fracture fixation plates introduced by Sherman and aimed toward stabilizing bone fractures and accelerating their healing.

Stainless Steel Kitchen Sinks Market Size to Expand Substantially Owing to Technological Innovations During 2020-2027 – Aerospace Journal

Stainless Steel Kitchen Sinks Market Size to Expand Substantially Owing to Technological Innovations During 2020-2027.

Posted: Tue, 03 Nov 2020 13:47:13 GMT [source]

Ferritic grades have a body-centred cubic construction while martensitic grades have a body-centred tetragonal structure and austenitic grades have a face centred cubic construction. Mixed acid Pickling bathtub typically containing a mix of nitric acid and hydrofluoric acid .

ASTM A240 304L stainless steel plate gauge Manufacturer

This alloy is beneficial in designing cardiovascular implants as a result of the ZrO2 passive film is thrombogenically suitable with blood. The corrosion resistance of this alloy can be improved as a result of presence of ZrO2 and Nb2O5, which strengthen the TiO2 movie fashioned on the floor. Hence, many modern titanium-primarily based alloys are β-stabilized so as to reduce the elastic modulus in direction of that of bone, although the commerce-off is usually lower put on resistance and fatigue energy. The glorious corrosion behaviour of Ti–13Nb–13Zr in different types of SBFs has been validated.

Relative keywords: 304l|304l stainless steel|aisi 304l|chemical composition of ss 304|sus 304l|composition of ss 304|ss304l|1.4307 stainless steel|304l stainless steel properties|ss 304 material properties|1.4307 material|304l steel|sa 240 gr 304|1.4306 material|304l chemical composition|ss 304l chemical composition|304l ss|304l stainless steel composition|sa 240 304l|astm a312 tp304l|yield strength 304|304l composition|uns s30403|304 stainless composition|304 stainless yield strength|ss 304 tensile strength|material 304l|1.4307 steel|s30403|aisi 304l stainless steel|sa 479 304|ss304l composition|1.4306 stainless steel|astm 304l|sa 240 type 304|ss 304 material composition|304l stainless steel price|astm a240 304l|ss304l properties|1.4307 chemical composition|sa312 tp304l|

ASTM A240 304L stainless steel plate phase diagram Manufacturer

The most essential characteristics of physique fluids that affect the corrosion of metallic implants are the chloride, dissolved oxygen and pH ranges. However, the dissolved oxygen ranges in blood are lower than in artificial solutions exposed to air atmosphere because of mixture with haemoglobin, which is the principle part of purple blood cells. The partial strain of oxygen in blood varies between one hundred to 40 mmHg for arterial and venous blood, respectively. Because most biomaterials depend on oxygen to repassivate, repassivation of metal surfaces is tougher beneath circumstances of low dissolved oxygen focus. Indeed, deaeration of the answer with high-purity nitrogen fuel to maintain low O2 focus was found to raised predict the in vivo efficiency of metal implants . Another gas, carbon dioxide , influences the corrosion in vivo by affecting the pH . Bicarbonate levels are about twenty instances larger in blood than in seawater .

Duplex stainless steels typically comprise 50% austenite and 50% ferrite (Figure 9a-c). The two-section combination also results in a marked refinement in the grain measurement of each the austenite and ferrite. This, together with the presence of ferrite, makes the material about twice as sturdy as widespread austenitic steels. They contain only about half the nickel focus of typical austenitic stainless steels; they’re due to this fact much less costly and less delicate to the value of nickel. With their high chromium focus, they’ve excellent pitting and crevice corrosion resistance, and to chloride stress corrosion.

Maximum pressure to fracture, A x The fracture pressure measured with initial measuring size x. M d30 The temperature at which 30 % deformation (strictly talking a real pressure of 0.3) causes the formation of 50 % martensite from an austenitic structure.

People also ask:cres 304l|a240 304l|304l yield strength|tensile strength of ss 304|ss 304l price|sa240 tp304l|1.4306 steel|ss 304 material specification|1.4307 stainless|sa213 tp304l|304l stainless steel chemical composition|aisi 304l mechanical properties|304l mechanical properties|ss 304 round bar price|304 and 304l|din 1.4307|aisi 304l chemical composition|sa 240 gr 304 material|304 round bar|ss 304l material properties|304l properties|a312 304l|304l stainless steel yield strength|aisi 304l 2b|ss304l material|304l sst|ss 1.4307|304l 2b|sa 240 gr 304l|astm s30400|304l carbon content|din 1.4306|aisi 304l properties|1.4307 aisi 304l|304l material properties|astm a312 304l|ss 304 round bar suppliers|aisi 304l composition|uns s30400 mechanical properties|sae 304l|type 304l|1.4307 stainless steel properties|sa 240 gr 304l mechanical properties|sst 304l|aisi 304l specification|1.4306 specification|astm a240 type 304l|304l austenitic stainless steel|1.4307 material properties|

Stainless Steel Floor & Shower Drains Market Size, Outlook and Opportunities in Grooming Regions with Forecast to 2027 – Aerospace Journal

Stainless Steel Floor & Shower Drains Market Size, Outlook and Opportunities in Grooming Regions with Forecast to 2027.

Posted: Tue, 03 Nov 2020 09:38:06 GMT [source]

Quickly, however, implant dysfunctionality because of corrosion, mechanical failure and poor biocompatibility was reported. In 1924, Zierold reported the effect of various metals on the encircling tissues. When inserted to bone, copper and nickel triggered significant discoloration of the surrounding tissue, while A240 SS304L steel plate MILL iron and steel dissolved quickly and aggravated tissue erosion. Although sure pure metals similar to gold, silver and aluminium did not trigger tissue discoloration, there were too delicate for many medical units. In 1926, the 18Cr–8Ni (wt%) chrome steel was first utilized in implants.

When titanium- and cobalt-based mostly alloys are coupled together in vivo, it might be anticipated that the passive titanium alloy would turn out to be the cathode whereas the much less passive cobalt alloy would bear accelerated corrosion. This means that the extent of accelerated corrosion caused to any steel from coupling to titanium ought to be small. Thus, titanium-cobalt combinations have been found secure both in vitro and in vivo, at least as long as no relative motion occurs .

astm a240 304l,astm a240 type 304l,a240 304l material cutting parts,a240-304 machine parts,a240 304 flat bar ,sa240 304l welded pipe,a240 grade 304 seamless pipe,a240-304l waterjet cutting disc,a240-304 material,a240 tp304l laser cutting parts,astm a240 304l mechanical properties,astm a240 304l chemical composition,astm a240 304l properties,a240 gr 304l Origin China,sa240 tp 304l angle bar,a240 type 304l square pipe,sa240 type 304l angle steel mill,astm a240 304l stainless steel,astm a240 304l density,astm a240 304l specification,a240 tp 304l in 7days delivery time,astm a240 304l plate,a240 304l material stock list,astm a240 grade 304l,astm a240 gr 304l stocklist thick 5-300mm,astm a240 304l yield strength,ASTM A240 304L stainless Manufacturer,ASTM A240 304L stainless steel plate Manufacturer,