ASTM A240 304L grade stainless Manufacturer

Content

ASTM A240 304L stainless steel plate poisson’s ratio Manufacturer

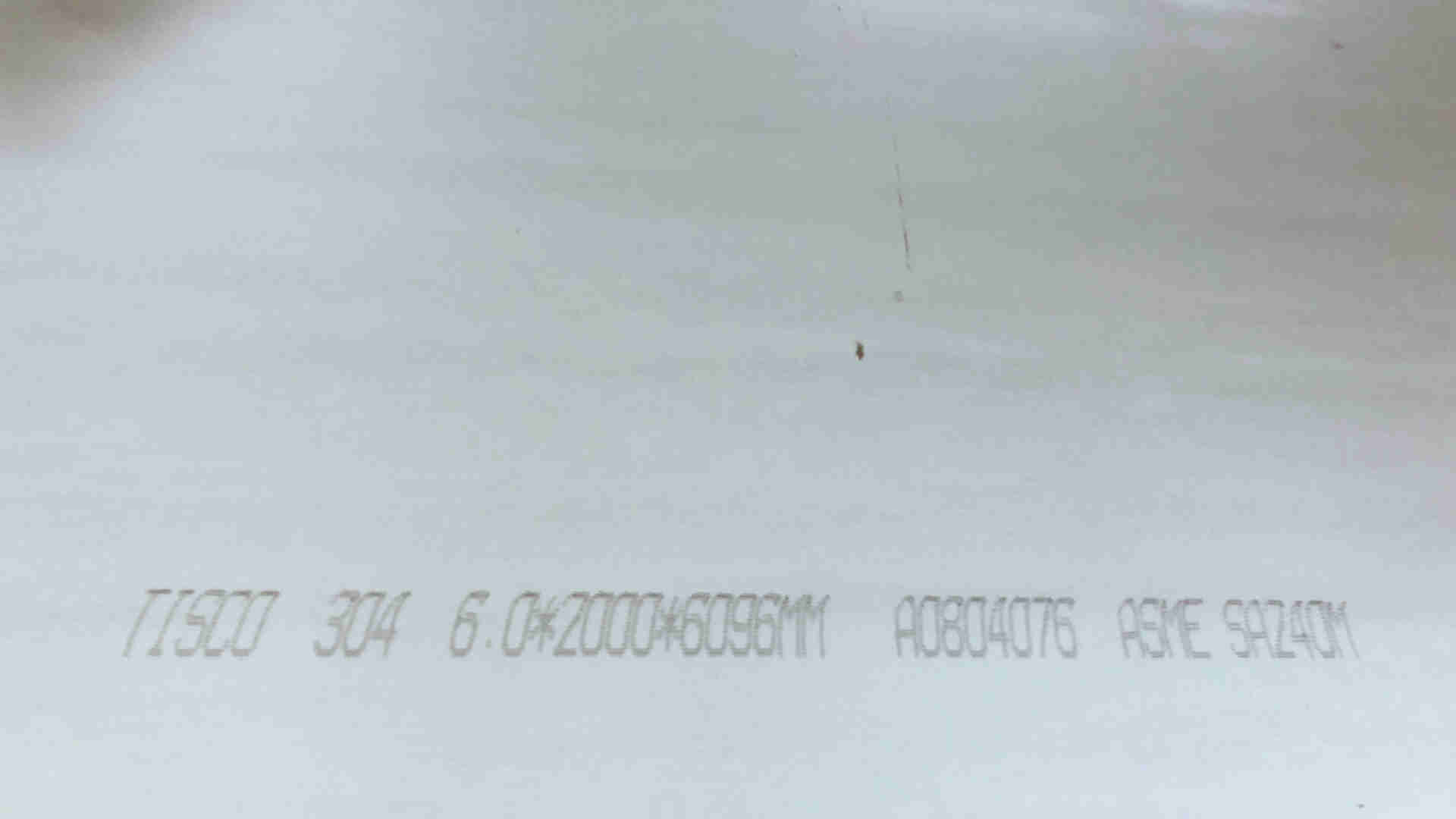

gangsteel supply astm a240 304l Stainless steel plate thickness 1mm to 300mm. the max width 2800mm. We also provide laserjet and water jet cutting for stainless grade astm a240 304l,astm a240 type 304l.a240 304l material cutting parts,a240-304 machine parts,a240 304 flat bar ,sa240 304l welded pipe.

a240 grade 304 seamless pipe,a240-304l waterjet cutting disc,a240-304 material,a240 tp304l laser cutting parts,astm a240 304l mechanical properties,astm a240 304l chemical composition,astm a240 304l properties,a240,gr 304l Origin China,sa240 tp 304l angle bar,a240 type 304l square pipe,sa240 type 304l angle steel mill,astm a240 304l stainless steel,astm a240 304l density,astm a240 304l specification.

aisi 304h metal plate worth We commit ourself to offer extra cheaper worth and more higher service at China metal market. 304 and 304L stainless steel plates are part of the austenitic family of stainless steel and they’re some of the versatile and widely used varieties of stainless plate. They are a relatively low value stainless product and utilized in a wide range of functions. 304 grades have excellent low temperature properties and reply nicely to hardening by cold working. 304 stainless-steel plate grades have good welding characteristics and submit weld annealing is not normally required to revive efficiency. 304 SS plates have wonderful corrosion resistance in a variety of different media.

- What is ASTM A240 304L Stainless steel grade?

304L stainless steel is a universal stainless-steel material.

Grade of 304L stainless steel:

The old standard JB / T 4237-1992 corresponds to 00Cr19Ni10

New standard GB / T 20878-2007 grade and chemical composition of stainless steel and heat resistant steel

And GB 24511 2009 stainless steel plate and strip for pressure equipment

Corresponding to 022cr19ni10, its carbon content is about 0.03%

The unified digital code s30403 is different from s30408 of 304

- What is Stainless steel ASTM a240 304l chemical composition and astm a240 304l mechanical properties?

Analysis of chemical composition% of 304L stainless steel

Carbon C: ≤ 0.03,

Silicon Si: ≤ 1.0,

Mn: ≤ 2.0,

Cr: 18.0-20.0,

Ni: 9.0-12.0,

Sulfur s: ≤ 0.03,

Phosphorus P: ≤ 0.045;

mechanical property

The mechanical properties of 304L stainless steel are as follows

Yield strength (n / mm2) ≥ 205

Tensile strength ≥ 520

Elongation (%) ≥ 40

Hardness HB ≤ 187 HRB ≤ 90 HV ≤ 200

The stainless steel rods

The stainless steel rods

The density was 7.93 g · cm-3

Specific heat C (20 ℃) 0.502 J · (g · C) – 1

Thermal conductivity λ / w (m ·℃) – 1 (at the following temperature / ℃)

20 100 500

12.1 16.3 21.4

Linear expansion coefficient α / (10-6 / ℃) (between the following temperatures / ℃)

20~100 20~200 20~300 20~400

16.0 16.8 17.5 18.1

The resistivity is 0.73 Ω· mm2 · M-1

Melting point 1398 ~ 1420 ℃

| Grade |

ASME SA240 304 Mechanical Strength |

||||

|

Yield |

Tensile |

Elongation |

Hardness, max |

||

|

A240 304L |

Min Mpa |

Mpa |

Min % |

Brinell |

Rockwell B |

|

205 |

515 |

40% |

201 |

92 |

|

|

|

|

|

|

|

|

|

Plate Grade |

The Element Maximum (%) |

||||||

|

C |

Mn |

P |

S |

Si |

Cr |

Ni |

|

|

ASTM A240 304L |

0.03 |

2.00 |

0.045 |

0.030 |

0.75 |

18.0-20.0 |

8.0-10.5 |

|

Mo |

N |

Cu |

|

|

|

|

|

|

|

0.10 |

|

|

|

|

|

|

- What is astm a240 304l density?

|

Steel Grade |

Density(g/cm3) |

|

304,304L,305,321 |

7.93 |

|

316,316L,347 |

7.98 |

|

405,410,420 |

7.75 |

|

409,430,434 |

7.7 |

What is astm a240 specification other grade?

- 304 is a kind of universal stainless steel, which is widely used to make equipment and parts with good comprehensive performance (corrosion resistance and formability).

- 301 stainless steel presents obvious work hardening phenomenon during deformation, which is used in various occasions requiring higher strength.

- 302 stainless steel is essentially a variety of 304 stainless steel with higher carbon content, which can obtain higher strength by cold rolling.

- 302B is a kind of stainless steel with high silicon content, which has high oxidation resistance at high temperature.

- 303se and 303se are free cutting stainless steels containing sulfur and selenium respectively, which are mainly used in the occasions requiring easy cutting and high surface finish. 303se stainless steel is also used to make machine parts requiring hot upsetting because it has good hot workability under such conditions.

- 304L is a variant of 304 stainless steel with low carbon content, which is used for welding. The lower carbon content makes the carbides precipitated in the heat affected zone near the weld to a minimum, and the precipitation of carbides may cause intergranular corrosion (welding corrosion) of stainless steel in some environments.

- 304n is a kind of stainless-steel containing nitrogen. The purpose of adding nitrogen is to improve the strength of steel.

- 305 and 384 stainless steels contain high nickel, and their work hardening rate is low, so they are suitable for various occasions with high requirements for cold formability.

- 308 stainless steel is used for welding rod.

- The contents of Ni and Cr in 309, 310, 314 and 330 stainless steels are relatively high in order to improve the oxidation resistance and creep strength of the steels at high temperature. However, 309S and 310S are variants of 309 and 310 stainless steels, but the difference is that the carbon content is low, so as to minimize the carbide precipitated near the weld. 330 stainless steel has high carburizing resistance and thermal shock resistance

- Type 316 and 317 stainless steels contain molybdenum, so their pitting corrosion resistance in marine and chemical industry environments is much better than that of 304 stainless steel. Among them, type 316 stainless steel includes low carbon stainless steel 316L and high strength stainless steel containing nitrogen.

- 316N and 316F, a free cutting stainless steel with high sulfur content.

- 321, 347 and 348 are stainless steels stabilized with titanium, niobium plus tantalum and niobium respectively. They are suitable for welding at high temperature. 348 is a kind of stainless steel which is suitable for nuclear power industry.

- The forging property of 304L stainless steel is poor and the deformation is difficult.

Supply ASTM A240, 304L, 316LN, 316H, 316Ti, 309S, 310S stainless steel

1. Steel Grade: A240 TP201, TP202, TP304L, TP309S, TP310S, TP316L, TP321, TP405, TP430, TP630, 2205, 2507

2. Available Size: thickness: 1-100mm, width: 500-2500mm, length: 1000-6000mm

3. Delivery Condition: No.1, No.2D, No.2B

4. Delivery Time: 3 days

5. Payment Item: TT or L/C

6. Trade Terms: FOB, CFR or CIF

7. Inspection: MTC, TPI (ABS, BV, LR, TUV, SGS), PMI Test.

If you need ASTM A240, TP304, TP316L, TP316H TP316Ti, TP309S stainless steel, please contact us freely. - Our supplies require going by way of strict high quality checks, thus providing lengthy service life with prime quality.

- Natural Steels is among the top producers and suppliers of Sheets, Plates & Coils from India.

- Natural Steels maintains a high-stock of Sheets, Plates & Coils and can export them at the most effective worth for 304/304L/304H aisi 304h metal plate price304H chrome steel price per kg in India, SS 304H supplierSuper 304h austenitic chrome steel.

- Our product range is available in unique and customizable sizes and dimensions of steel plates or sheets.

Scale or slag that varieties from welding processes is removed with a stainless steel wire brush. Normal carbon steel wire brushes will leave carbon metal particles within the surface which is able to ultimately produce surface rusting. For extra extreme purposes, welded areas should be treated with a descaling answer such as a mix of nitric and hydrofluoric acids, and these must be subsequently washed off.

Stainless Steel 904L Plates has Good resistance to pitting and crevice corrosion, superb resistance to stress corrosion cracking, good resistance to intergranular corrosion, good formability and weldability, maximum service temperatures of 450 degree C . The greater chromium, molybdenum and nitrogen content of 317LMN improve its capacity to resist pitting and crevice corrosion within the presence of chlorides and other halides. The Pitting Resistance Equivalent together with Nitrogen quantity is a relative measure of pitting resistance. The following chart provides a comparison Alloy 317LMN and different austenitic stainless steels. Alloy 304/304L (UNS S30400/S30403) is the most broadly utilized “18-eight” chromium-nickel austenitic stainless steel. It is an economical and versatile corrosion resistant alloy appropriate for a wide range of general function applications.

ASTM A240 304L grade stainless steel plate Manufacturer

Stainless Steel UNS S43000 Sheet can be used in varied functions similar to Dishwasher linings, Refrigerator cupboard panels, Element helps, Stove trim rings and chimney liners, Automotive trim and equipment parts, etc. Alloy 304/304L resists atmospheric corrosion, in addition to, moderately oxidizing and decreasing A240 SS304L steel plate MILL environments. The alloy has excellent resistance to intergranular corrosion within the as-welded condition. Alloy 304/304L has glorious energy and toughness at cryogenic temperatures. The 18-eight alloys have been used very efficiently in contemporary waters containing low ranges of chloride ion.

Cusinium, Tealyra, FORLIFE, Hiware, Fitz and Floyd.

Posted: Tue, 03 Nov 2020 17:36:00 GMT [source]

People also ask:cres 304l|a240 304l|304l yield strength|tensile strength of ss 304|ss 304l price|sa240 tp304l|1.4306 steel|ss 304 material specification|1.4307 stainless|sa213 tp304l|304l stainless steel chemical composition|aisi 304l mechanical properties|304l mechanical properties|ss 304 round bar price|304 and 304l|din 1.4307|aisi 304l chemical composition|sa 240 gr 304 material|304 round bar|ss 304l material properties|304l properties|a312 304l|304l stainless steel yield strength|aisi 304l 2b|ss304l material|304l sst|ss 1.4307|304l 2b|sa 240 gr 304l|astm s30400|304l carbon content|din 1.4306|aisi 304l properties|1.4307 aisi 304l|304l material properties|astm a312 304l|ss 304 round bar suppliers|aisi 304l composition|uns s30400 mechanical properties|sae 304l|type 304l|1.4307 stainless steel properties|sa 240 gr 304l mechanical properties|sst 304l|aisi 304l specification|1.4306 specification|astm a240 type 304l|304l austenitic stainless steel|1.4307 material properties|

astm a240 type 304l

Relative keywords: 304l|304l stainless steel|aisi 304l|chemical composition of ss 304|sus 304l|composition of ss 304|ss304l|1.4307 stainless steel|304l stainless steel properties|ss 304 material properties|1.4307 material|304l steel|sa 240 gr 304|1.4306 material|304l chemical composition|ss 304l chemical composition|304l ss|304l stainless steel composition|sa 240 304l|astm a312 tp304l|yield strength 304|304l composition|uns s30403|304 stainless composition|304 stainless yield strength|ss 304 tensile strength|material 304l|1.4307 steel|s30403|aisi 304l stainless steel|sa 479 304|ss304l composition|1.4306 stainless steel|astm 304l|sa 240 type 304|ss 304 material composition|304l stainless steel price|astm a240 304l|ss304l properties|1.4307 chemical composition|sa312 tp304l|

304/304L also resists moderately aggressive natural acids corresponding to acetic. The 18 to 19 % of chromium which these alloys contain supplies resistance to oxidizing environments corresponding to dilute nitric acid, as illustrated by information for Alloy 304 under. 430F is the free-machining model of this grade, out there in bar form for use in computerized screw machines. Grade 434 is the molybdenum bearing model of Grade 430 and has the identical helpful mixture of properties. ASTM A240 SS 430 sheets and plates have a wide selection of functions.

You can even select from plate, metal plate, and coil 309s stainless-steel sheet, in addition to from 300 sequence, 2b, and four hundred sequence 309s stainless steel sheet, and whether or not 309s stainless-steel sheet is bending, chopping, or welding. The common 2B finish chrome steel sheet inventory out there are grade 304, 309S, 316, 430, and 201 in mill edge or slit fringe of width 1000mm, 1220mm, 1500mm, 1800mm, 2000mm. Metline is a number one manufacturer and provider of 2B finish stainless-steel sheets manufactured in compliance with ASTM, ASME and EN requirements.

Stainless metal pipe is considered to be stronger and can also slot in larger temperatures and pressures simply. Alloy 410 Coils is used for highly stressed elements with good corrosion resistance and strength. Applications requiring average corrosion resistance and high mechanical properties are ideal for these Grade 410 Stainless Steel Sheets. Meanwhile, typical uses of Grade 410 Stainless Steel Coils embody flat springs, knives, kitchen utensils and hand instruments.

Despite their corrosion resistance, stainless steels want care in fabrication and use to maintain their surface look even under regular circumstances of service. Alloy 309 (23% Cr thirteen.5% Ni) or nickel-base filler metals are used in becoming a member of the 18-8 austenitic alloys to carbon metal. The austenitic stainless steels are thought of to be the most weldable of the excessive-alloy steels and can be welded by all fusion and resistance welding processes. The Alloys 304 and 304L are typical of the austenitic stainless steels.

Some of the tests we conduct on SS 310S Coils embrace Hardness Test, Flattening Test, Mechanical Testing Such as Tensile of Area etc. Stainless steel 310 coils are austenitic in design, and thus have high resistance to oxidation at high temperatures. Crafted from 25 per cent chromium and 20 per cent nickel, these SS 310S sheets are extraordinarily proof against corrosion. The SS 310 Plates are also significantly immune to nitric acid, sulfuric acid, poisonous gasses and steam. A perfect blend of tungsten, molybdenum, vanadium, and chromium assist the coils in steady service withstand warmth as much as 1150 degrees Celsius.

Generally, a hundred ppm chloride is considered to be the limit for the 18-8 alloys, particularly if crevices are present. For the extra extreme conditions of upper chloride ranges, lower pH, and/or larger temperatures, alloys with higher molybdenum content corresponding to Alloy 316 should be thought of.

ASTM A240 304L stainless chemistry Manufacturer

astm a240 304l,astm a240 type 304l,a240 304l material cutting parts,a240-304 machine parts,a240 304 flat bar ,sa240 304l welded pipe,a240 grade 304 seamless pipe,a240-304l waterjet cutting disc,a240-304 material,a240 tp304l laser cutting parts,astm a240 304l mechanical properties,astm a240 304l chemical composition,astm a240 304l properties,a240 gr 304l Origin China,sa240 tp 304l angle bar,a240 type 304l square pipe,sa240 type 304l angle steel mill,astm a240 304l stainless steel,astm a240 304l density,astm a240 304l specification,a240 tp 304l in 7days delivery time,astm a240 304l plate,a240 304l material stock list,astm a240 grade 304l,astm a240 gr 304l stocklist thick 5-300mm,astm a240 304l yield strength,ASTM A240 304L stainless Manufacturer,ASTM A240 304L stainless steel plate Manufacturer,