A240 s-n curve 316l stainless steel plate stockist

Content

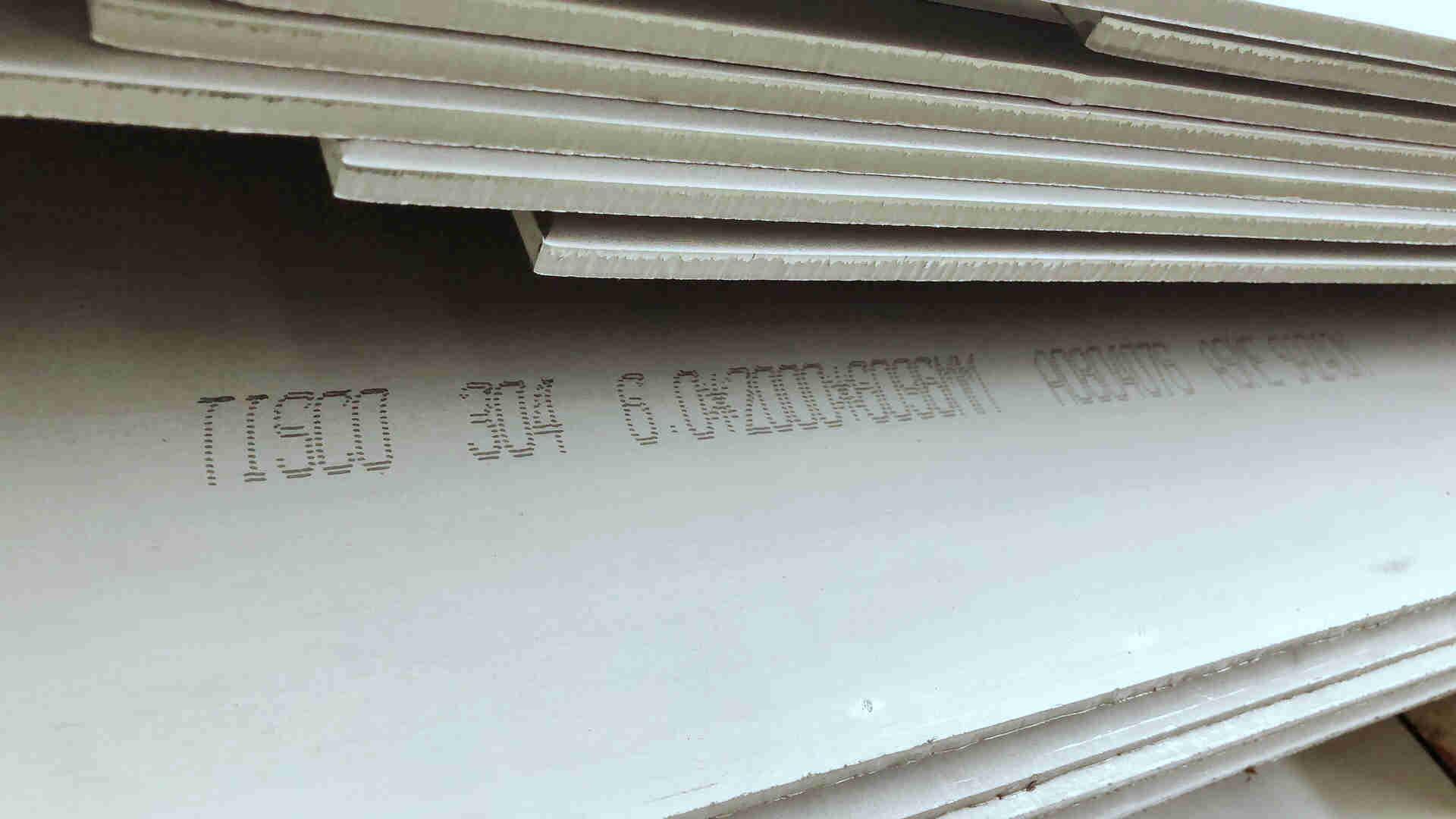

Gangsteel are the large stainless steel plate supplier. our main Grade A240 316L A240 SS316L, A240 TP316L A240 Type 316L aisi 316L Stainless plate, SQ pipe, cutting parts, Stainless disc and angle.a240 316l stainless,aisi 316l stainless steel,a240-316l 7days delivery time,a240-316l cutting parts,a240 316l machined parts,316l stainless steel astm,316/316l stainless steel,316l 316 H beam.

Thus, welding can be carried out without any threat of intergranular corrosion. Weld metallic with a fully austenitic construction is more susceptible to cracking through the welding operation. For this purpose, Type 321 is designed to resolidify with a small amount of ferrite to attenuate cracking susceptibility. Columbium stabilized stainless steels are more vulnerable to sizzling cracking than titanium stabilized stainless steels. Type 321 is stabilized against chromium carbide formation by the addition of titanium. CS 316 offers higher strength and higher creep resistance at larger temperatures than CS 304. CS 316 also possesses glorious mechanical and corrosion properties at sub-zero temperatures.

316l stainless steel plate specifications

When thin gauge material is welded the time within the temperature vary of 800 to 1500° F (427 to 816° C) is so brief that with most corroding media the unstabilized kind material is mostly satisfactory. The extent to which carbide precipitation could also be harmful relies upon upon the length of time the alloy was exposed to 800 to 1500° F (427 to 816° C) and upon the corrosive environment. Even the longer heating occasions involved in welding heavy gauges are not dangerous to the unstabilized “L” grade alloys the place the carbon content material is stored to low amounts of 0.03% or much less.

These acids must be completely rinsed off the floor after cleansing. For most ductility, the higher annealing vary of 1800 to 2000° F (928 to 1093° C) is beneficial.

Gangsteel supply the stock stainless steel plate. A240 316L OR SAE 316L grade stainless steel, sometimes referred to as A4 stainless steel or marine grade stainless steel, is the second most common austenitic stainless steel after 304/A2 stainless steel. Its primary alloying constituents after iron, are chromium (between 16–18%), nickel (10–12%) and molybdenum (2–3%), with small (<1%) quantities of silicon, phosphorus & sulfur also present. The addition of molybdenum provides greater corrosion resistance than 304, with respect to localized corrosive attack by chlorides and to general corrosion by reducing acids, such as sulfuric acid. 316L grade is the low carbon version of 316 stainless steel. When cold worked, 316L can produce high yield and tensile strengths similar to Duplex stainless grades.

Marlin Steel acquires nearby wire handle maker, plans big factory expansion – Baltimore Business Journal

Marlin Steel acquires nearby wire handle maker, plans big factory expansion.

Posted: Mon, 16 Nov 2020 18:33:00 GMT [source]

One identified exception is very oxidizing acids similar to nitric acid to which the molybdenum-bearing stainless steels are much less resistant. The term “carbon metal” may also be utilized in reference to steel which isn’t stainless-steel; in this use carbon metal could embrace alloy steels.

If, despite these precautions, it’s believed that residual stresses could impair the function of the weldment, it is recommended that the complete structure be resolution annealed. In options containing halides similar to chloride and bromide ions, standard stainless steels can be readily attacked by native corrosion within the type of pitting corrosion, crevice corrosion or stress corrosion cracking . In acid environments, the presence of halides also accelerates general corrosion. The annealing temperature range for Type 321 is 1800 to 2000° F (928 to 1093° C). As emphasized, nonetheless, annealing in the 800 to 1500° F (427 to 816° C) temperature range doesn’t lead to a susceptibility to intergranular attack.

A240 cres 316l plate factory

Gangsteel production range for stainless, our max thickness 300mm, the max width 2600mm. Thickness 3mm to 300mm. 316/316L steel has outstanding corrosion resistant properties, whether it is atmospheric or oxidizing environment, even for marine atmosphere, it shows excellent corrosion resistance in welded state. Normally 316/316l steel shows no magnetic in annealed condition, cold drawn or cold rolling process may make it with little magnetic, and it can be fixed with further processing.

A240 316l stainless plate price|A240 316l stainless steel plate properties|A240 316l stainless steel plate price per kg|A240 316l stainless steel plate weight|A240 316/316l plate|A240 plate 4 mm 316l|A240 316l tread plate|A240 ss 316l plate unit weight|A240 316l stainless steel plate mechanical properties|A240 316l stainless steel plate specifications|A240 316l stainless steel plate thickness|A240 ss 316l plate density|A240 ss 316l plate price in india|A240 ss 316l plate weight|A240 316l plate suppliers|A240 316l plate weight|A240 316l plate thicknesses|A240 316l plate price|A240 ss 316l plate chemical composition|A240 aisi 316l plate|A240 cres 316l plate|A240 316l diamond plate|A240 ss 316l plate weight calculator|A240 a240 316l plate|A240 astm 316l plate|A240 316l plated stainless steelA240 ss 316l plate|A240 316l ss plate|A240 316 stainless plate|A240 316l stainless steel plate|A240 316l stainless plate|A240 316l plate specification|A240 316l stainless steel plate price|A240 316l steel plate|A240 ss 316l plate rate

- What ASTM A240 Type 316L

A240 316L is a grade of stainless steel, AISI 316L is the corresponding American grade, and sus 316L is the corresponding Japanese grade.

The unified digital code in my country is S31603, the standard brand is 022Cr17Ni12Mo2 (new standard), and the old brand is 00Cr17Ni14Mo2, which means that it mainly contains Cr, Ni, and Mo, and the number indicates the approximate percentage. The national standard is GB/T 20878-2007 (current edition).

- What a240 316L density? The a240 316L density is 7.98g/cm3;

- What is A240 316L yield?

Tensile strength σb (MPa): ≥480

Conditional yield strength σ0.2 (MPa): ≥177

Elongation δ5 (%): ≥40

Reduction of area ψ (%): ≥60

Hardness: ≤187HB; ≤90HRB; ≤200HV

Density: 7.98g/cm3;

Specific heat capacity ratio (20℃): 0.502J/(g*K)

| Steel Grade |

Mechanical Property |

|||||||

|

ASTM(A240M) |

Others(JIS) |

Tensile Properties |

Hardness |

Bend Test |

||||

|

Yield StrengthMPa |

Tensile StrengthMPa |

Elongation% |

HBW |

HRBW |

||||

|

316 |

SUS316 |

≥205 |

≥515 |

≥40 |

≤217 |

≤95 |

― |

|

|

316L |

SUS316L |

≥170 |

≥485 |

≥40 |

≤217 |

≤95 |

― |

|

|

316H |

|

≥205 |

≥515 |

≥40 |

≤217 |

≤95 |

― |

|

Gangsteel relative keywords.

A240 316l|A240 aisi 316l|A240 ss316l|A240 sus 316l|A240 316l steel|A240 316l surgical steel|A240 1.4404 stainless steel|A240 316l ss|A240 316l stainless|A240 tp 316l|A240 316l stainless steel price|A240 316 316l|A240 316 stainless tubing|A240 sa 240 316l|A240 1.4404 steel|A240 astm a312 tp 316l|A240 s31603|A240 aisi 316l stainless steel|A240 a312 tp 316l|A240 astm 316l|A240 er 316 l|A240 316l stainless steel price per kg|A240 gr 316|A240 din 1.4404|A240 316l stainless steel pipe|A240 sa240 316|A240 astm a312 tp 316|A240 316l grade stainless steel|A240 astm a240 316l|A240 1.4435 stainless steel|A240 a240 316l|A240 astm 316 stainless steel|A240 316l stainless steel tubing|A240 1.4404 stainless|A240 316l stainless steel sheet|A240 sa 240 gr 316|A240 316 stainless rod|A240 metal 316l|A240 316 stainless sheet|A240 316 stainless plate|A240 316l sst|A240 ss 1.4404|A240 316l stainless steel plate

- What astm a240 316l equivalent?

|

EQUIVALENT ASTM A240 |

|||||||

|

No |

JIS G4304 |

ASTM |

UNS |

KS |

EN10095 |

AS |

CNS |

|

10 |

SUS309S |

309S |

S30908 |

STS309S |

1.4833 |

309S |

309S |

|

11 |

SUS310S |

310S |

S31008 |

STS310S |

1.4845 |

310S |

310S |

|

12 |

SUS316 |

316 |

S31600 |

STS316 |

1.4401 |

316 |

316 |

|

13 |

SUS316Ti |

316Ti |

S31635 |

– |

1.4571 |

316Ti |

316Ti |

|

14 |

SUS316L |

316L |

S31603 |

STS316L |

1.4404 |

316L |

316L |

|

15 |

SUS316N |

316N |

S31651 |

STS316N |

– |

316N |

316N |

|

16 |

SUS316LN |

316LN |

S31653 |

STS316LN |

1.4429 |

316LN |

316LN |

|

17 |

SUS316J1 |

– |

– |

STS316J1 |

– |

316J1 |

316J1 |

|

18 |

SUS316J1L |

– |

– |

STS316J1L |

– |

– |

316J1L |

|

19 |

SUS317 |

317 |

S31700 |

STS317 |

– |

317 |

317 |

|

20 |

SUS317L |

317L |

S31703 |

STS317L |

1.4438 |

317L |

317L |

- What does a240 mean? A-240 Heat-Resisting Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels. SA-263 Corrosion-Resisting Chromium Steel Clad Plate, Sheet, and Strip.

|

Grade |

ASTM A240 316L Chemical Composition |

|||||||||

|

ASTM(A240M) |

Others(JIS) |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Others |

|

316 |

SUS316 |

≤0.08 |

≤0.75 |

≤2.00 |

≤0.045 |

≤0.030 |

10.0/14.0 |

16.0/18.0 |

2.00/3.00 |

N≤0.10 |

|

316L |

SUS316L |

≤0.030 |

≤0.75 |

≤2.00 |

≤0.045 |

≤0.030 |

10.0/14.0 |

16.0/18.0 |

2.00/3.00 |

N≤0.10 |

|

316H |

0.04/0.10 |

≤0.75 |

≤2.00 |

≤0.045 |

≤0.030 |

10.0/14.0 |

16.0/18.0 |

2.00/3.00 |

||

Gangsteel other products

A240 316 stainless pipe|A240 a240 316|A240 316l grade surgical steel|A240 astm a240 316|A240 316l surgical stainless steel|A240 316l tube|A240 sa 312 tp 316l|A240 grade 316l|A240 titanium 316l|A240 sae 316l|A240 316l pipe|A240 316l surgical grade stainless steel|A240 sae 316l stainless steel|A240 astm a479 316|A240 tp 316|A240 1.4404 aisi 316l|A240 sa 479 316l|A240 sa 240 gr 316l|A240 sa 240 tp 316l|A240 alloy 316l|A240 type 316l stainless steel|A240 316 and 316l|A240 aisi 1.4404|A240 steel 1.4435|A240 sus 316l stainless steel|A240 sa 213 tp 316l|A240 astm 316l stainless steel|A240 ss316l pipe|A240 316l plate|A240 ss316 and ss316l|A240 aisi 316l ss|A240 astm a312 gr tp316l|A240 316l austenitic stainless steel|A240 sa 240 tp 316|A240 a276 316l|A240 astm a269 tp316|A240 316 sheet|A240 a269 tp316|A240 astm a240 tp 316|A240 316l astm|A240 316 stainless bar|A240 cres 316l|A240 316l 1.4404 stainless steel|A240 316 and 316l stainless steel|A240 316l stainless steel hypoallergenic|A240 316 stainless round bar|A240 a240 tp316l|A240 astm a240 tp316l|A240 ss 316l grade|A240 316 stainless flat bar|A240 stainless steel grade 1.4404|A240 304 316l|A240 sst 316l

- A240 304 VS A240 316l SAE 316L, What is different of 304 AND 316L?

Essentially, Grade 304 is an austenitic chromium alloy which is also known as an "18/8" stainless as the make-up of the steel is 18% chromium and 8% nickel. The chromium content promotes the material’s considerable resistance to the effects of corrosion and oxidation.

The two most commonly used stainless steels 304 and 316L (or 1.4308 and 1.4408 corresponding to German/European standards). The main difference in chemical composition between 316 and 304 is that 316L contains Mo, and it is generally recognized that 316L has better corrosion resistance.

It is more corrosion resistant than 304 in high temperature environment.

Therefore, in high temperature environments, engineers generally choose 316 material components.

A240 316L is commonly used in chemical and petrochemical industry, in food processing, pharmaceutical equipment, medical devices, in potable water, wastewater treatment, in marine applications and architectural applications near the seashore or in urban areas.

TW shares only twin certified 316 / 316L grade plate licensed to ASTM A240 and ASME SA240. Representative brief time elevated temperature tensile properties for Alloys 316, 316L, and 317L of the following analyses are proven under.

A240 316l stainless steel jewelry wholesale plate stockist

The stabilized Type 321 alloy presents an answer to polythionic acids SCC by resisting sensitization throughout elevated temperature service. For optimum resistance, these alloys must be used in the thermally stabilized condition if service associated circumstances may lead to sensitization.

The most stress that an object is anticipated to help is known as the allowable stress. For instance, the floors in a library may need an allowable stress of one hundred fifty kilos per square foot. We inventory Stainless steel plate supplier .1875″ – 2″ thick x forty eight”, 60″ and 96″ extensive as much as 240″ long. Our water jet cutting capabilities for stainless plate are up to 6″ x 120 x a hundred and forty four.

Harriman’s historic Ranch Bridge replaced with steel

A240 316l stainless steel non magnetic plate stockist

Generally, one hundred ppm chloride in aqueous environments is taken into account to be the restrict for each the unstabilized and the stabilized alloys, notably if crevices are present. Higher ranges of chloride ion would possibly cause crevice corrosion and pitting. For extra severe situations of upper chloride level, decrease pH and/or higher temperature, alloys with molybdenum, corresponding to Type 316, should be thought-about. The stabilized Type 321 alloy passes the a hundred hour, 5% neutral salt spray check (ASTM-B-117) with no rusting or staining of samples. However, publicity of these alloys to salt mists from the ocean could be expected to cause pitting and crevice corrosion accompanied by severe discoloration.

A240 316l stainless steel price per pound|A240 sa 240 type 316l|A240 aisi 316l steel|A240 316l round bar|A240 a4 316l|A240 a240 gr 316l|A240 ss 316l pipe price|A240 1.4404 ss|A240 316l din|A240 asme 316|A240 cf3m 316l|A240 316 stainless angle|A240 sandvik 316l|A240 316l 316ti|A240 astm a479 316l|A240 316l sheet|A240 316 surgical stainless steel|A240 a213 tp316l|A240 spj 316l|A240 ss316 ss316l|A240 316l 2b|A240 1.4432 stainless steel|A240 316l marine grade stainless steel|A240 type 316l|A240 sa316l|A240 a312 316|A240 aluminium 316l|A240 ss 316 and 316l|A240 aws 316l|A240 ss316l stainless steel|A240 tp316l stainless steel pipe|A240 sa 479 gr 316|A240 316l stainless steel pipe supplier|A240 s31603 sst|A240 a358 316l|A240 astm a213 tp316l|A240 astm a240 type 316l|A240 a240 tp 316|A240 316 seamless tubing|A240 sa 249 316l|A240 ss 316l sheet price|A240 316l ug|A240 1.4435 aisi 316l|A240 a 312 tp 316l|A240 316l plate|A240 316 plate

- Cooling must be sufficiently fast via the 1500 to 800°F (816 to 427°C) range to avoid reprecipitation of chromium carbides and provide optimum corrosion resistance.

- For the Alloys 316 and 317L the solution anneal is completed by heating within the 1900 to 2150°F (1040 to 1175°C) temperature range adopted by air cooling or a water quench, relying on section thickness.

- The austenitic stainless steels are offered within the mill annealed condition ready for use.

- Heat therapy may be essential throughout or after fabrication to take away the effects of cold forming or to dissolve precipitated chromium carbides ensuing from thermal exposures.

We have a customer who’s wanting an old design re-built however with the allowable stress values used from 2001 Edition. For these reasons the diploma of stabilization and of resulting safety could also be less pronounced when Type 321 is employed. When the unstabilized chromium-nickel steels are held in or slowly cooled through the range of 800 to 1500° F (427 to 816° C), chromium carbide is precipitated at the grain boundaries. In the presence of sure strongly corrosive media, these grain boundaries are preferentially hooked up, a common weakening of the metallic outcomes, and a whole disintegration may happen. Type 321 has been developed for functions where the unstabilized chromium-nickel steels, similar to Type 304 could be vulnerable to intergranular corrosion. General Corrosion The Type 321 alloy provides comparable resistance to general, total corrosion because the unstabilized chromium nickel Type 304.

Gangsteel had 3000tons raw stock material and we can produce A240 316L Stainelss steel plate with faster delivery time. 7-10days we can be ready for delivery. If you have inquiry for 316L stainless steel material, please contact us.